6

The Improved

Clay Stove

6.1 Background

The improved clay stove project started in 2000, in

rural Al Fashir. This stove was seen as an appropriate

technology and an alternative to the traditional 3

brick stove. This traditional stove was very inefficient

and comparative tests that have been performed have

highlighted this difference with the improved clay

stove being 55-60 % more efficient. It is also seen as

the most appropriate solution in terms of affordability

and ease of dissemination through the training of

trainers.

In 2003 the size of the project was increased due to

huge displacement caused by the Darfur conflict. This

led to greater pressure on the environment and severe

risks for IDPs (normally women) when collecting the

ever decreasing supply of wood. By 2007 Practical

Action had trained more than 3000 women in villages

and IDP camps in the manufacture of the Improved

Clay Stove.

6.2 Instructions

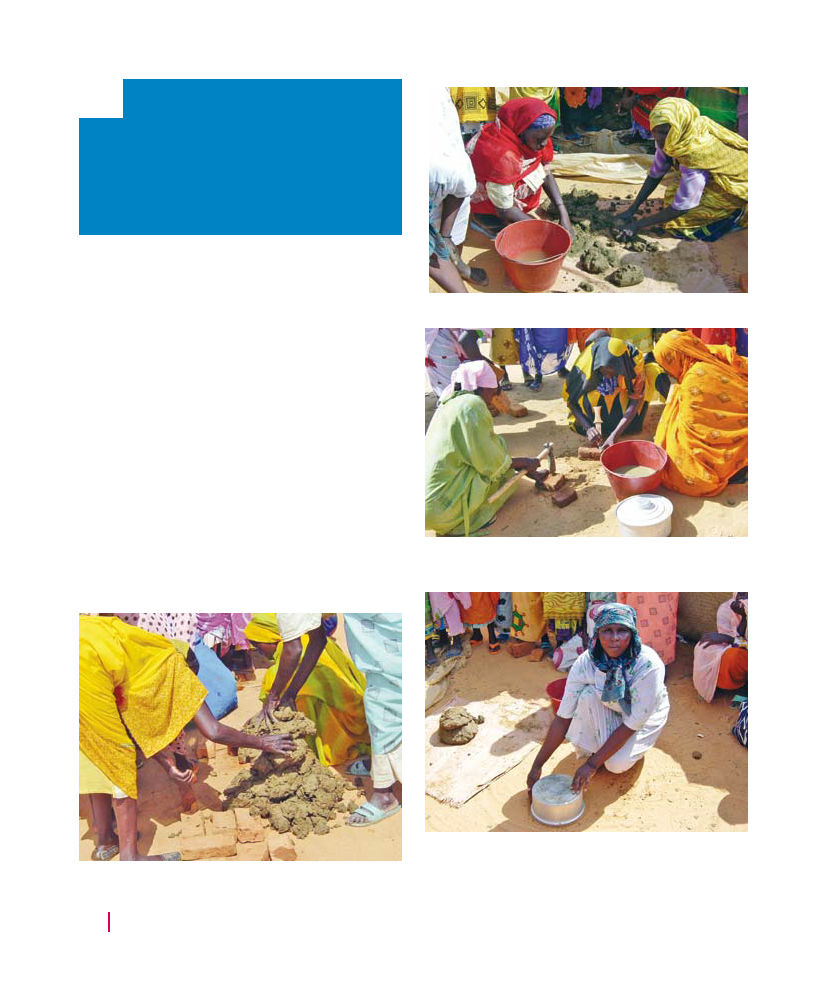

Pic 52. The clay is kneaded on a plastic bag.

Pic 53. The red bricks are marked with a knife and cut

into thirds using a small axe.

Pic 51. The bricks and clay are gathered.

20

CLAY BASED

TECHNOLOGIES

Pic 54. A line is drawn around the outside of the saucepan

most frequently used in the kitchen to determine the size

of the stove.